Manufacturing Clean Energy Blog

Manufacturing Clean Energy is the official blog of the Clean Energy Manufacturing Analysis Center (CEMAC). It features insights from CEMAC staff, partners, and guests. To contribute to Manufacturing Clean Energy.

Green Energy: What an Investor Needs to Know

March 9, 2021

By Emma Elgqvist, CEMAC Analyst

Obtaining energy is one of the most relevant for modern civilization. Green energy has become a real trend in the last 5-7 years. It is designed to save many countries from hydrocarbon dependence. Therefore, it will be useful for investors to know what it is and how to make money on investments in this developing economy sector.

When Comparing Costs of Automotive Lithium-Ion Batteries, Know the Context

May 30, 2020

By Emma Elgqvist, CEMAC Analyst

When comparing the costs of lithium-ion batteries for electric vehicles, understanding the context is crucial. In the latest CEMAC blog, analyst Emma Elgqvist compares modeled and market prices for Li-ion batteries and observes that market factors—not manufacturing costs—are currently influencing pricing decisions. It's all based on a recent factsheet develop for the Department of Energy.

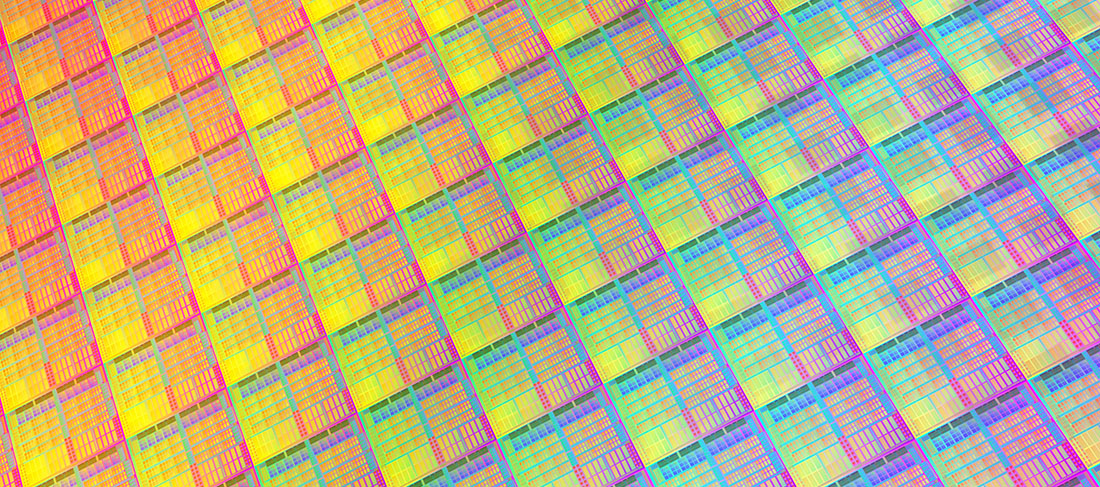

SiC-based Motor Drives: Manufacturing the Next Generation of Industrial Energy Savings

April 12, 2020

By Kelsey Horowitz, Timothy Remo, and Samantha Reese, CEMAC Analysts

Silicon-carbide power electronics aren't just the next generation of energy savings in industrial motors and motor drives. They're a great, high-tech manufacturing opportunity. But where will this opportunity materialize? In this blog, CEMAC analysts break down the most competitive regions for silicon-carbide manufacturing, as presented in our latest report. And they look to the future, exploring the potential impacts of new innovations in silicon-carbide power electronics.

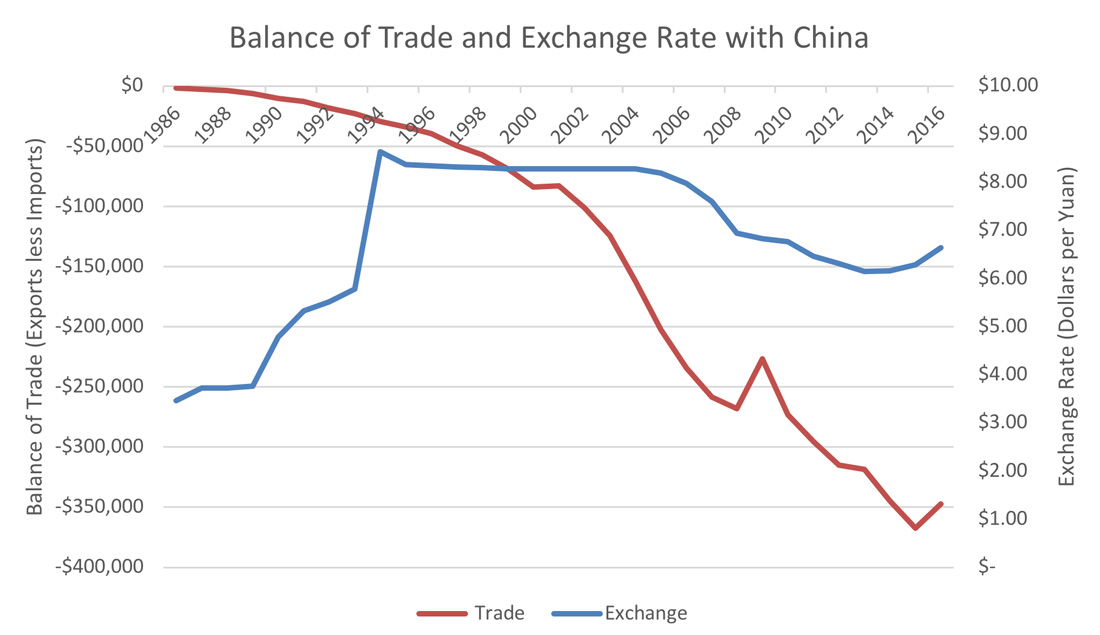

Currency Fluctuations and Trade

February 23, 2020

By David Keyser, CEMAC Analyst

We hear about currency fluctuations and its possible impact on trade in the business news frequently.

Economic theory indicates that prices and consumption are linked. When prices are low, people usually buy more of a desired good than when prices are high. Part of a price includes the value of the currency with which it is purchased. For example, if the U.S. dollar is less expensive relative to the currency of the trading partner, that partner can use less of their money to purchase goods or services from the United States. Conversely, if the dollar is more expensive they must use more of their currency. (There are many articles published about this topic, including How the Dollar Impacts Commodity Prices.)

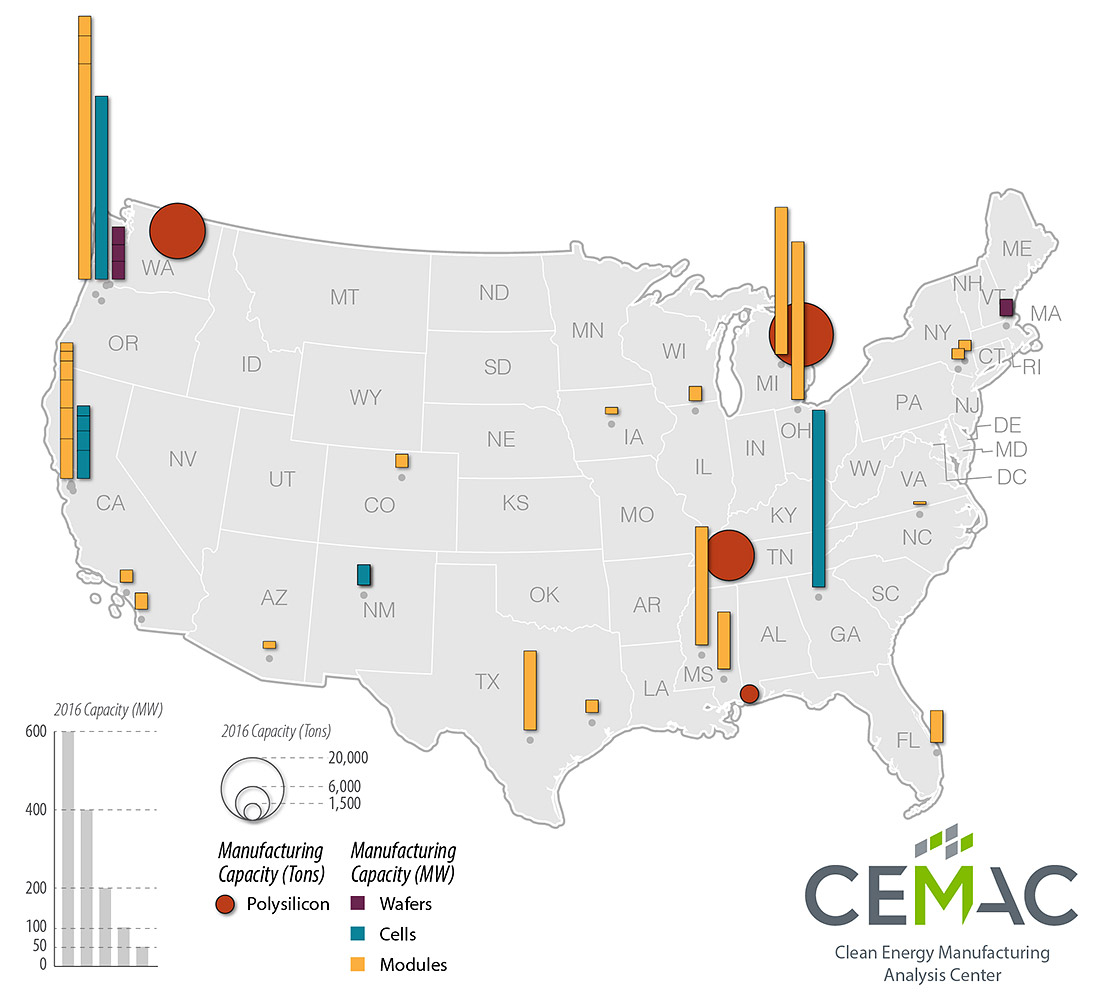

Photovoltaics Made in the USA

March 27, 2020

by Sadie Fulton, CEMAC analyst

The American solar photovoltaic market is dynamic and rapidly growing. In 2016, the U.S. solar industry installed 14.8 gigawatts (GW) of solar, a 97% increase over the capacity installed in 2015. Solar's growth trajectory and increasing market share continue to excite electricity producers and consumers alike. Yet, despite this success, PV manufacturing is not an industry for the faint of heart.

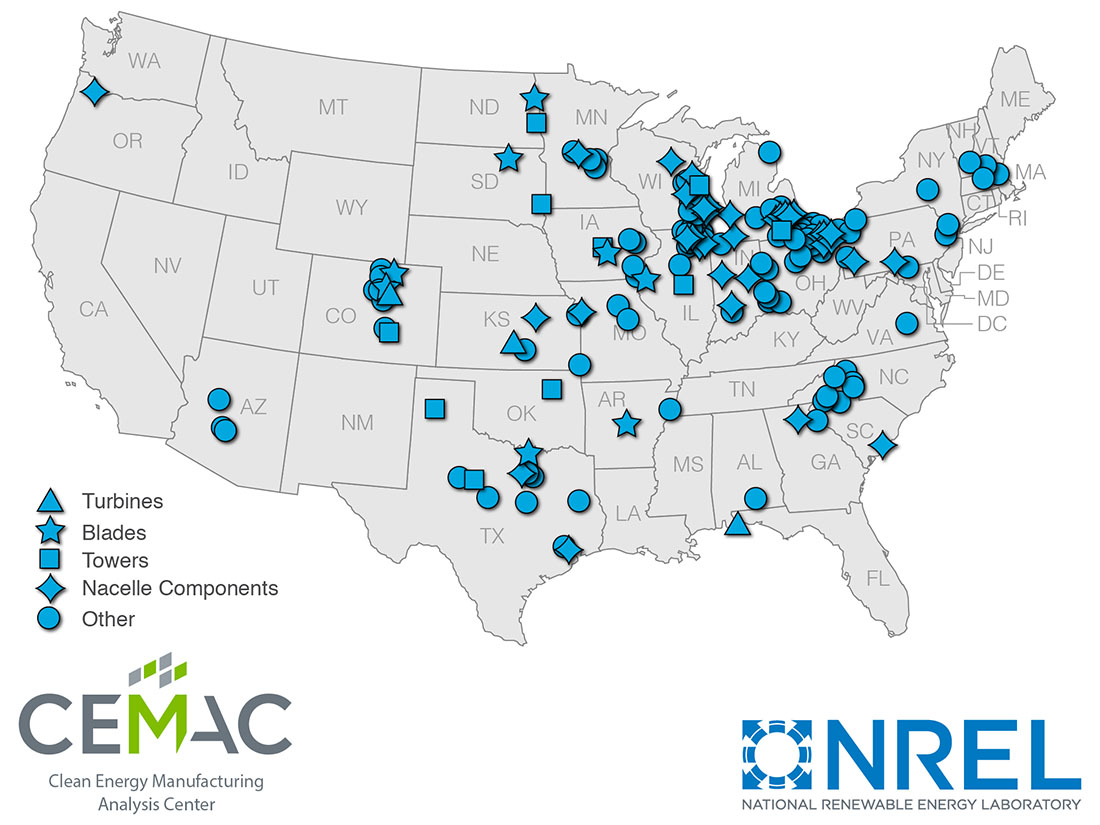

Wind Turbines Made in the USA

April 18, 2020

By Parthiv Kurup and Timothy Remo, CEMAC Analysts

The wind industry in the United States is growing rapidly, supported by a large domestic manufacturing sector. Now, manufacturers are seeking new ways to make their turbines bigger and more efficient. What role could additive manufacturing play in the future of the American wind energy industry? In this blog, CEMAC analysts highlight the state of U.S. wind manufacturing and how new advanced manufacturing technologies such as additive manufacturing could change it.

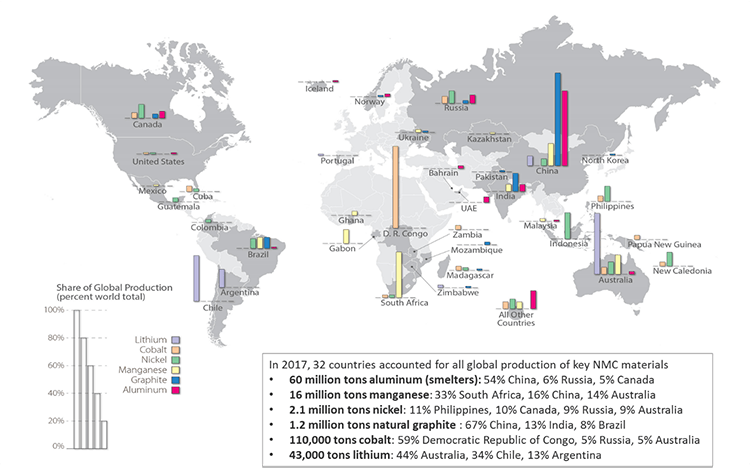

Are there enough materials to cover li-ion batteries?

August 15, 2020

By Ahmad Mayyas, National Renewable Energy Laboratory

This blog is an updated version of the 2016 blog we published about li-ion battery raw materials.

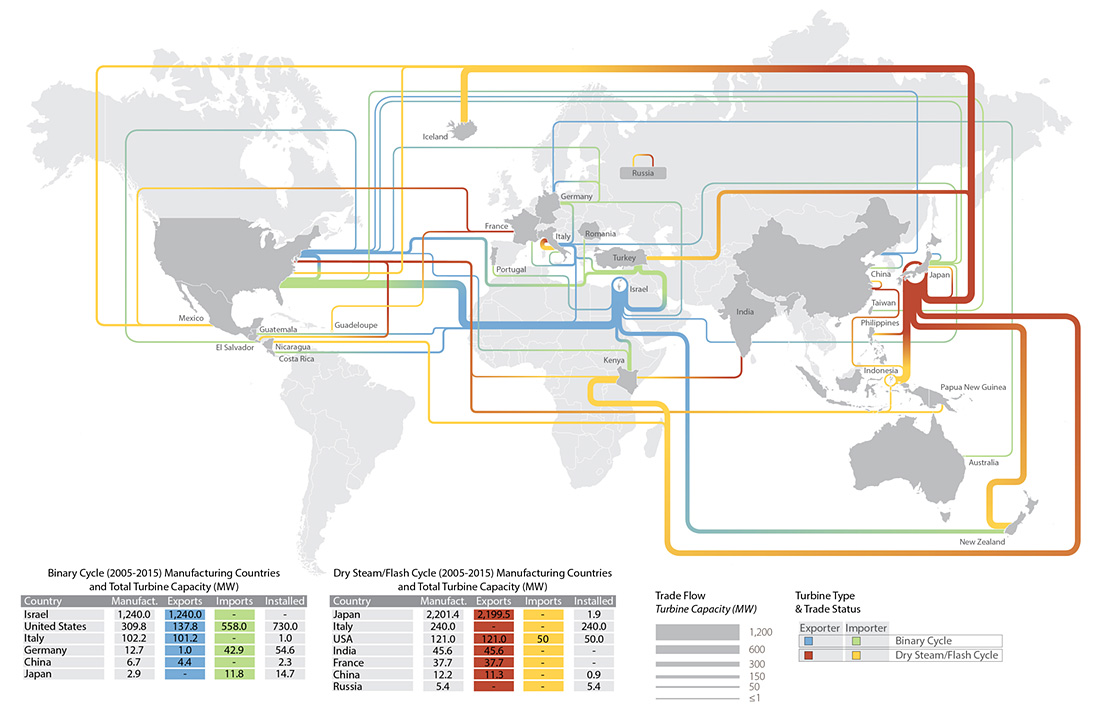

Geothermal Power Plant Turbines: First Look at the Manufacturing Value Chain

June 3, 2016

By Sertac Akar, National Renewable Energy Laboratory

In the 10 years ending in December 2015, global geothermal power capacity increased by 4.4 GW to 13.3 GW. See the major players in turbine manufacturing in this first look at CEMAC's geothermal market analysis.

Entrepot Trade and Its Effect on Trade Flow Perception

November 18, 2016

By Samantha Reese, CEMAC Analyst

An essential part of every CEMAC project is to examine the global trade flow of a product's critical components as well as the end product itself. In Fiscal Year 2016, CEMAC studied the value chain of integrated light-emitting diode (LED) lighting.

Hydropower Turbine Market and Trade Values: A closer look at small hydro turbines in the U.S.

December 14, 2016

By Parthiv Kurup, NREL, and Megan Johnson, ORNL

Hydropower has been a long-term stable power generation source in the U.S. for decades, and research shows there is significant electricity generation potential from powering domestic, non-power hydro dams, which would utilize smaller turbines. This potential growth in the U.S. and international market demand for small hydropower turbines could offer greater opportunities for local and more energy-efficient manufacturing practices, both within the U.S. and for export.

Bio-Based Carbon Fiber: An Exciting New Product, But There's Work to Do

September 29, 2016

By Anelia Milbrandt and Sam Booth, CEMAC

Carbon fiber, also known as graphite fiber, is a lightweight, strong, and flexible material used in both structural applications (load-bearing) and non-structural applications (e.g., thermal insulation). The high cost of precursor materials and manufacturing, however, have kept carbon fiber in a niche market for applications that are mostly limited to high-performance structural products.

Reflecting on The Wealth of Nations

December 9, 2015

By Tom Catania, Executive in Residence, Erb Institute for Global Sustainable Enterprise, University of Michigan

Smith describes how the collective impact of individuals pursuing their own interest contributes to the collective good.