Wind Turbines Made in the USA

April 18, 2017

By Parthiv Kurup and Timothy Remo, CEMAC Analysts

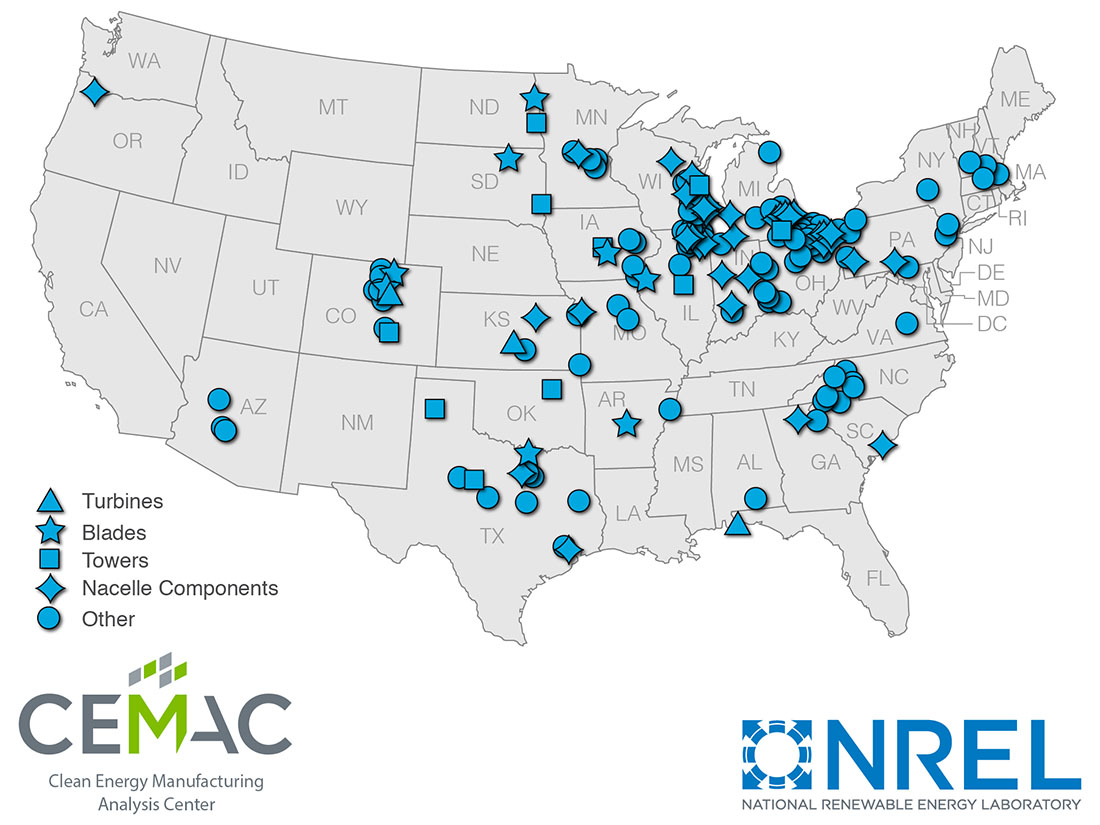

Because it is difficult to transport the large components of a wind turbine (blades can be greater than 50 meters) over long distances to the project sites, local domestic manufacturing has been vital for the growth of the U.S. wind industry. U.S. utility-scale wind manufacturers also export turbine generator sets to Canada, Brazil, Mexico, and UK at a level of approximately $578 million in 2014 (see Figure 6-3 on page 33 of the linked report).

Additive manufacturing (AM)—also called 3D printing—could spur further growth in the wind industry and could augment existing supply chains. AM, which produces parts by laying down material in layers, has the potential to further reduce future wind component costs and the cost of the electricity wind turbines produce. As Big Area AM (BAAM) and next-generation Wide and High AM (WHAM) develop, it may be possible to direct print utility-scale blade molds and interchangeable blade tips on-site, which could allow for customization of wind blades across a wind farm. This blade optimization across the site could increase the electricity generated by the wind farm. Other wind components that could benefit from AM research include the nacelle, magnets for generators, heat exchangers, and perhaps even concrete structures!

Recently, a CEMAC team (of Oak Ridge National Lab and National Renewable Energy Lab analysts) studied initial, high-value wind components and systems that would benefit from AM. Tooling is a prime target for AM to be utilized with large-scale wind components. While AM can be done with polymers, metals, composites, and ceramics, only polymers are currently applicable for the large scale of wind components. AM (especially with polymers) is currently well-suited for producing complex, expensive, and time-sensitive components with low production volumes. Blade molds fit all of these characteristics.

The images below show an additively manufactured blade mold demonstrator designed and created by Sandia National Laboratory and Oak Ridge National Lab with funding from the Department of Energy's Wind Energy Technologies Office.

To learn more about the potential for AM in the wind industry and the potential costs of AM blade molds, pick up CEMAC's upcoming 2017 Highlights Report, scheduled for release in spring 2017.