Manufacturing Clean Energy Blog

Manufacturing Clean Energy is the official blog of the Clean Energy Manufacturing Analysis Center (CEMAC). It features insights from CEMAC staff, partners, and guests. To contribute to Manufacturing Clean Energy, contact us.

Hydropower Turbine Market and Trade Values: A closer look at small hydro turbines in the U.S.

December 14, 2016

By Parthiv Kurup, NREL, and Megan Johnson, ORNL

Hydropower has been a long-term stable power generation source in the U.S. for decades, and research shows there is significant electricity generation potential from powering domestic, non-power hydro dams, which would utilize smaller turbines. This potential growth in the U.S. and international market demand for small hydropower turbines could offer greater opportunities for local and more energy-efficient manufacturing practices, both within the U.S. and for export.

Workforce Development and Investment is a Win-Win for All

December 7, 2016

By Heather Head and Chuck Kurnik, NREL

Transitioning to a new clean energy economy requires investment in workforce development, as new technologies such as solar panels and wind turbines are manufactured, installed, and operated. Training for skilled workforce performance is essential to meet the needs of these clean energy industries.

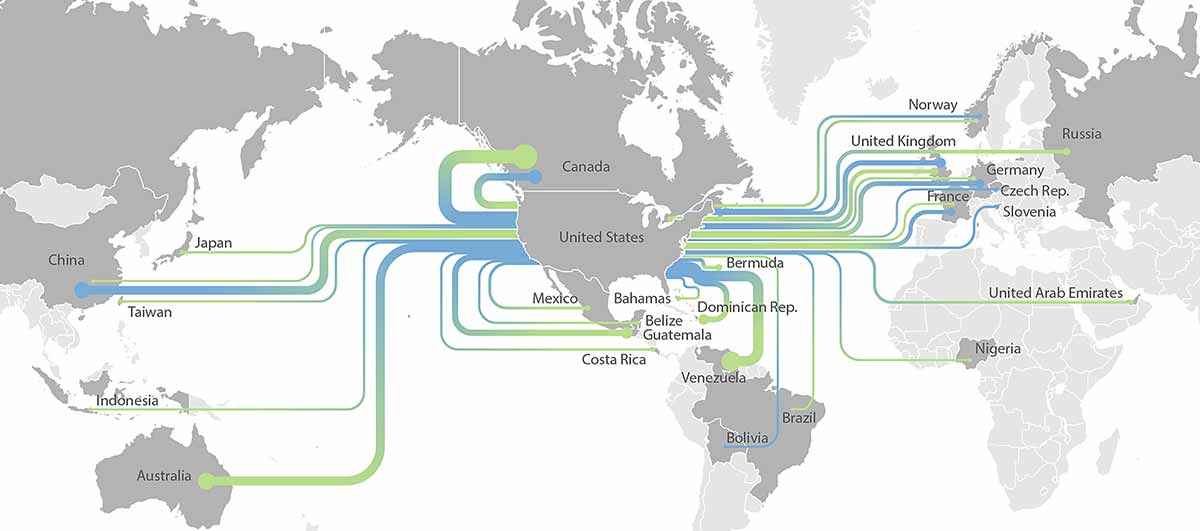

Entrepot Trade and Its Effect on Trade Flow Perception

November 18, 2016

By Samantha Reese, CEMAC Analyst

An essential part of every CEMAC project is to examine the global trade flow of a product's critical components as well as the end product itself. In Fiscal Year 2016, CEMAC studied the value chain of integrated light-emitting diode (LED) lighting.

Clean Energy and Manufacturing for Society: Notes from the 2016 STS Forum

October 25, 2016

By Jill Engel-Cox, Ph.D., CEMAC Director

This month, I had the great honor to participate in the 2016 Science and Technology in Society (STS) Forum in Kyoto, Japan, where experts from across the globe engaged in discussion on energy, health, information technology, and engineering.

Bio-Based Carbon Fiber: An Exciting New Product, But There's Work to Do

September 29, 2016

By Anelia Milbrandt and Sam Booth, CEMAC

Carbon fiber, also known as graphite fiber, is a lightweight, strong, and flexible material used in both structural applications (load-bearing) and non-structural applications (e.g., thermal insulation). The high cost of precursor materials and manufacturing, however, have kept carbon fiber in a niche market for applications that are mostly limited to high-performance structural products.

Modeling Industrial Materials Flows to Reduce Energy Demand and Carbon Emissions

August 29, 2016

By Rebecca Hanes and Alberta Carpenter, NREL

NREL's Materials Flow through Industry (MFI) tool provides valuable insight into supply chain energy, greenhouse gases, resources and materials to inform future research on clean manufacturing technologies.

Mitigating Maritime Shipping Impacts on Manufacturing Costs

August 1, 2016

By Samantha Reese, CEMAC Analyst, and Maggie Mann, CEMAC Technical Director

Manufacturing is not just making products in a single facility. It includes the complex logistics of shipping materials from processing facilities and subcomponents from a network of suppliers.

Democratization of Manufacturing: Notes from the American Energy & Manufacturing Competitiveness Summit

June 3, 2016

By Jill Engel-Cox, Ph.D., CEMAC Director

On May 12, I had the privilege of attending and participating in a panel at the 2016 American Energy & Manufacturing Competitiveness (AEMC) Summit at the City College of New York's Great Hall. It was especially exciting to share some of CEMAC's progress and findings since it was formally launched at the previous AEMC Summit in September 2015.

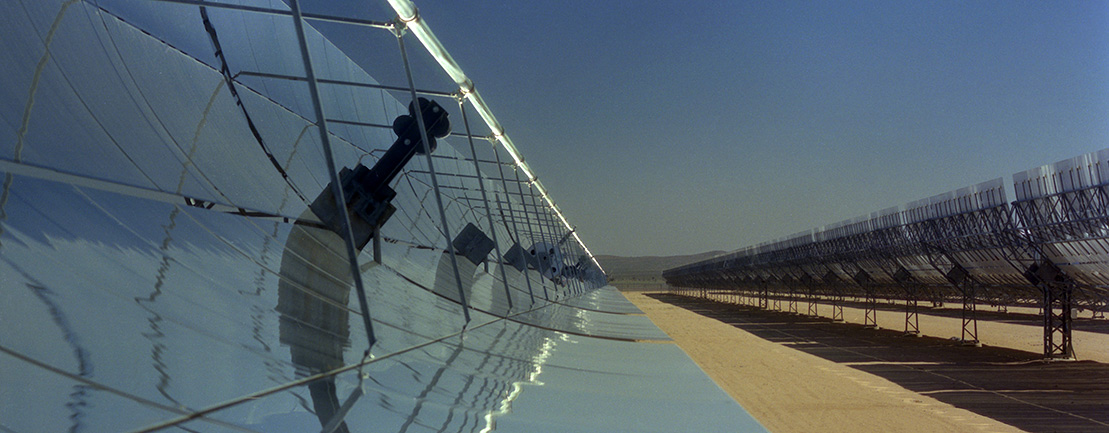

On the Path to SunShot: Assessing Opportunity in PV Manufacturing

June 24, 2016—When the SunShot Initiative launched in 2011, it set the goal of making solar electricity cost-competitive with conventional sources of electricity by 2020. Since then, solar deployment has grown more than tenfold in the U.S. with more than one million solar installations currently operating across the country. The cost of solar energy has also dropped as much as 65%. As a result, the industry is approximately 70% of the way toward meeting the SunShot 2020 goals.

On the Path to SunShot is a series of eight reports that examines the lessons learned in the first five years of the initiative and the challenges and opportunities the industry faces in the final five. One of the reports—Emerging Opportunities and Challenges in U.S. Solar Manufacturing—finds that improvements to standard PV modules have produced deep cost reductions, but dramatic innovations in module design and manufacturing are required for cost reductions to continue. That finding could mean opportunity for U.S. PV and CSP manufacturers, as the United States is a global leader in PV and CSP R&D and patent production.

On the Path to SunShot reports were produced through a collaborative effort by researchers at four national laboratories: the National Renewable Energy Laboratory, Lawrence Berkeley National Laboratory, Sandia National Laboratories, and Argonne National Laboratory. The NREL researchers who led the manufacturing assessment also contribute to CEMAC.

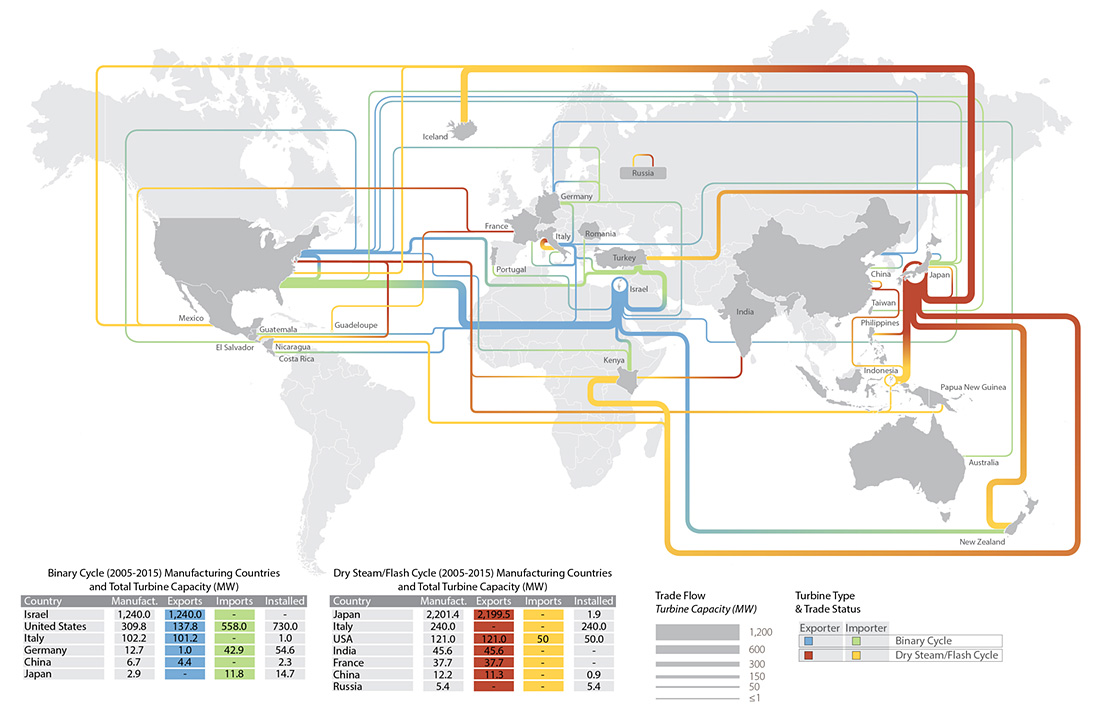

Geothermal Power Plant Turbines: First Look at the Manufacturing Value Chain

June 3, 2016

By Sertac Akar, National Renewable Energy Laboratory

In the 10 years ending in December 2015, global geothermal power capacity increased by 4.4 GW to 13.3 GW. See the major players in turbine manufacturing in this first look at CEMAC's geothermal market analysis.

Minimum Sustainable Price: Understanding Sustainable Business Practices in Clean Energy Technology

May 12, 2016

By Kelsey Horowitz, Mike Woodhouse, and Ran Fu (National Renewable Energy Laboratory) and Tonio Buonassisi (Massachusetts Institute of Technology)

CEMAC researchers explain minimum sustainable price and why it can be crucial to industry sustainability.

AEMC Summit Spotlights CEMAC Carbon Fiber Analysis and Program Director Engel-Cox

May 12, 2016 — CEMAC's latest clean energy analysis was highlighted today at the American Energy and Manufacturing Competitiveness 2016 Northeast Regional Summit in New York. Global Carbon Fiber Composites Supply Chain Competitiveness Analysis identifies key opportunities in the carbon fiber supply chain where resources and investments can help advance the clean energy economy.

The report focuses on four application areas—wind energy, aerospace, automotive, and pressure vessels—that top the list of industries using carbon fiber and carbon fiber reinforced polymers and are particularly relevant to the mission of U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy (DOE EERE). For each of the four application areas, the report addresses the supply and demand trends within that sector, supply chain, and costs of carbon fiber and components.

The report was prepared for CEMAC by Sujit Das, Josh Warren, and Devin West of the U.S. Energy Department's Oak Ridge National Laboratory, and Susan M. Schexnayder of the University of Tennessee, Knoxville.

CEMAC Program Director Jill Engel-Cox also participated in the AEMC summit as a panelist in a session titled "Fireside Chat: Mapping out Global Energy & Manufacturing Trends." Organized by the Council on Competitiveness, the 2016 AEMC summit is the fourth premier, annual, event dedicated to building momentum around American innovation, progress and competitiveness in energy and manufacturing.

Do You Have New Windows? CEMAC Needs Your Help

April 18, 2016—Did you recently replace the windows in your home? If so, you can help advance research that could reduce the cost of replacement windows.

CEMAC is studying the costs of installing energy-efficient windows in homes—from the cost of the windows themselves to costs for installation and labor—and we're collecting as much data as possible. We are searching for copies of actual invoices from energy-efficient window installations.

We are particularly interested in receiving invoices that break out the cost of the windows from the installation costs, but invoices that show total costs will also be helpful. Our team is only interested in cost information and wants to ensure your privacy is respected; please black out any personal information and submit your invoice to Catherine Burke.

This research is being done as part of the U.S. Department of Energy's Clean Energy Manufacturing Initiative for the Building Technologies Office.

Lithium Ion Battery Key Elements — More Than Just Lithium

April 13, 2016

By Emma Elgqvist, National Renewable Energy Laboratory

NREL's Emma Elqgvist shares early results of CEMAC's latest study on the manufacturing value chains of automotive lithium ion batteries, an essential part of the transition to a clean energy economy.

Built, Regional Cost Factors Drive Lithium-ion Battery Manufacturing Location Competitiveness

April 8, 2016—CEMAC's newest report, Automotive Lithium-ion Cell Manufacturing: Regional Cost Structures and Supply Chain Considerations, explores factors that drive regional competitiveness in automotive lithium-ion battery (LIB) cell production by modeling cell manufacturing cost and minimum sustainable price and examining development of LIB supply chains and current LIB market conditions. The study shows that factors driving the cost competitiveness of LIB manufacturing locations are mostly built, though some regional costs are significant and should be considered. Learn more about this study.

How Will c-SI PV Production Affect Silver Demand and Prices?

A new article in PV-Tech (subscription required) explores how increased c-Si PV module production might affect future silver demand and prices, as well as the impacts on total c-Si module manufacturing costs. To evaluate how PV's changing demand for silver might affect future silver prices, and the impact in terms of manufacturing costs, researchers from Colorado School of Mines and the U.S. Department of Energy's National Renewable Energy Laboratory compiled some scenarios of silver's contribution to c-Si PV cell manufacturing costs on the basis of projected changes in demand and price as a result of changes in material intensity.

The analysis indicates that an expansion of c-Si production from 55GW/year to 250GW/year results in a 0.05-0.7¢/W increase in manufacturing costs because of higher silver prices.

FY15 Research Highlights: Discuss Findings in April 5 Webinar

Update: April 6, 2016—This webinar has concluded, but you can still view the webinar slides and contact us for an audio recording.

The FY15 Research Highlights report showcases key findings from four major studies on the manufacturing of clean energy technologies. Three of these focused on the end product: solar photovoltaic modules, wind turbines, and automotive lithium-ion batteries. The fourth area focused on a key material for manufacturing clean energy technologies, carbon fiber.

Webinar Details

- Date and time: April 5 at 8:30 a.m. Mountain time (10:30 a.m. Eastern standard time).

- Panelists: Sujit Das (ORNL), Emma Elgqvist (NREL), Jill Engel-Cox (CEMAC), Margaret Mann (NREL).

The FY15 Research Highlights report also previews work that is underway to support CEMAC's mission: to provide robust, data-rich insights on clean energy markets and global trade flows. In 2016 CEMAC and our partners plan to conduct new or additional analysis on technologies such as:

- Biomass-derived chemicals and products (NREL, Argonne National Laboratory, Pacific Northwest National Laboratory)

- Carbon fiber for lightweighting (Oak Ridge National Laboratory, NREL)

- Conventional and advanced heat pumps (NREL)

- Energy-efficient insulated windows (Lawrence Berkley National Laboratory, NREL)

- Geothermal binary power plants (NREL)

- Hydrogen filling stations (NREL, Argonne National Laboratory)

- LED commercial lighting (NREL)

- Small hydropower generation (Oak Ridge National Laboratory, NREL)

- Solar PV (NREL)

- Vehicle lithium-ion batteries (NREL, Argonne National Laboratory)

- Wide bandgap devices for clean energy technologies (NREL, Oak Ridge National Laboratory)

Helping U.S. Advanced Industries, which are Crucial for the U.S. Economy

March 4, 2016

By Derek Hill, National Science Foundation

The performance of high tech and R&D-intensive U.S. industries may provide insight to the successes and challenges of regions with clean energy manufacturing.

From Classroom to Factory Floor

January 29, 2016

By Jill Engel-Cox, Ph.D., Clean Energy Manufacturing Analysis Center

The U.S. Energy Department's Industrial Assessment Centers (IACs) program celebrates 40 years of service to industry this year.

NREL Patents Method for Continuous Monitoring of Materials During Manufacturing

The Energy Department's National Renewable Energy Laboratory (NREL) was recently issued a patent for a novel method that rapidly characterizes specialized materials during the manufacturing process. This approach significantly improves on standard quality control techniques by allowing for complete monitoring of materials without interrupting workflow.

"This technique enables materials manufacturers to detect potential problems early without slowing or stopping the manufacturing process," said Bhushan Sopori, an NREL materials performance scientist and inventor of the On-line Monitoring in Solar Cell and Fuel Cell Manufacturing technology. Commercial benefits of implementing this invention could extend to a number of industries including manufacturing of fuel cell components, semiconductor wafers, glass, and coatings.

Notes from the Solar Future Symposium

January 21, 2016

By Michael Woodhouse, National Renewable Energy Laboratory

Last November, I traveled to Saudi Arabia, a leading producer of oil, to deliver a keynote talk at the Solar Future 2015 Symposium.