Systems Analysis of Manufacturing Supply Chains

August 8, 2020

By James McCall, CEMAC Analyst

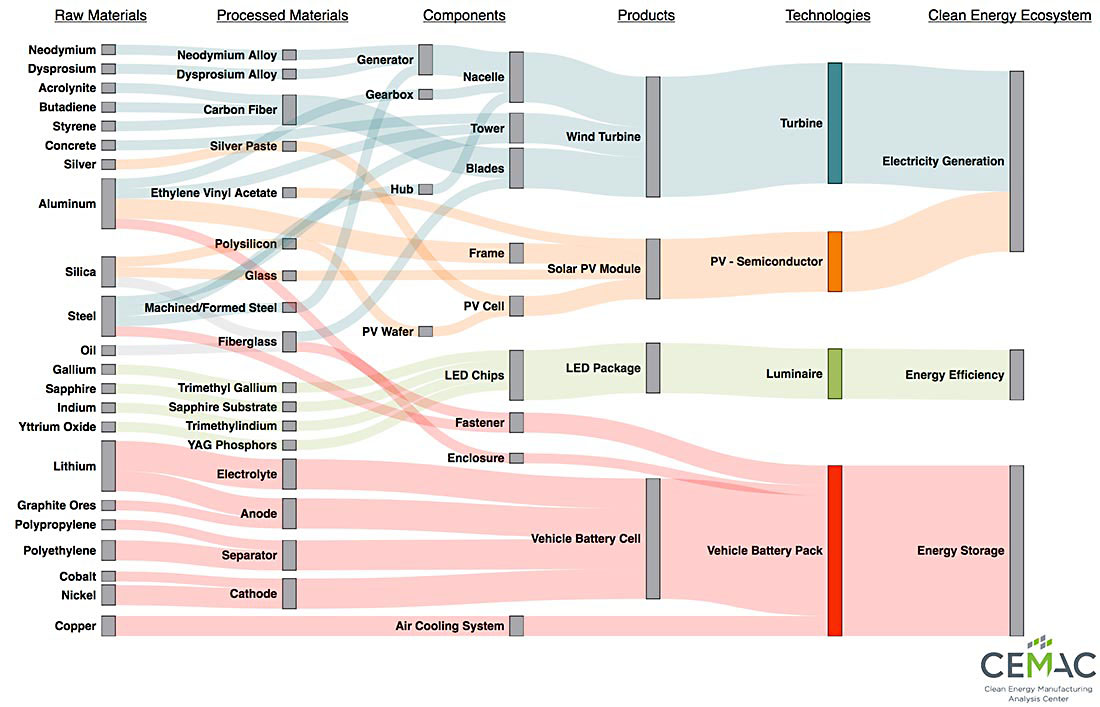

As deployment of advanced energy technologies increases, analysis of their integration into power systems has become an important field of study to inform policy and reliably operate power grids. However, the manufacturing of these advanced technologies has not been widely studied as a comprehensive system. Specifically, the interactions of products and materials within advanced energy technology supply chains with other similar product supply chains are not well understood. For example, turbine manufacturing is important to wind, hydro, and gas combined cycle power plants. Semiconductors are a key component of photovoltaic panels, LED lighting, and power electronics. To assess these and similar supply chain interactions, CEMAC has begun to conduct analyses to capture the materials, products, supply chains, and their linkages across the clean energy manufacturing landscape.

Our plan is to map the clean energy manufacturing landscape in enough detail to explore interconnections between supply chains of related and unrelated clean energy technologies. Our first effort aims to provide a visualization of the clean manufacturing system to inform policy makers and industry decision-making processes. For instance, our work could help a manufacturer of a technology find new interactions or supply chain barriers from other manufacturing process that, if addressed, would open up new business areas or inform supply chain resiliency planning.

For the technologies we choose to represent in the CEMAC manufacturing system analysis, we will map out critical components of their value chain, from raw materials, to process materials, to subcomponents and, finally, clean energy products. Each clean energy product will be grouped by enabling technology to capture similarities between value chains.

As a proof of concept, CEMAC has created a Sankey diagram of the technologies studied in our recent Benchmark report, seen below. In this diagram, an interesting example relates to permanent magnets sometimes used in wind turbines and other clean technologies. Materials needed for permanent magnets (neodymium, lanthanum, and cobalt) have serious supply-constraint issues that may restrict the market penetration of some clean energy technologies, such as wind turbines or electric vehicle drives. While this diagram does not indicate current supply chain constraints, the addition of further technologies to this diagram could highlight constraints or similarities within current and future manufacturing product value chains.

Image created by Rob Spencer, NREL

In future efforts, we will add technologies to the diagram in these enabling categories:

- Electricity Generation (concentrating solar power, geothermal, natural gas turbines, etc.)

- Energy Efficiency (combined heat and power systems, wide band gap power electronics, etc.)

- Energy Storage (molten salt, compressed air energy storage, etc.)

- Fuels/Transportation (hydrogen electrolysis, biofuels, electric drive trains, etc.)

- Smart Grid Technologies (smart meters, power controllers, microgrids, etc.)

We have also identified several potential pathways for expanding the technology system map and incorporating data for the benefit of policy makers and industry. Some of these potential pathways are:

- Interactive Online Map: Create an interactive website for visualization that can show linkages of products and materials across all value chains.

- Global Manufacturer Database: Identify top manufacturers for critical products and materials across supply chains with location and country data.

- Supply Chain Quantification: Incorporate product, subcomponent, or process material "recipes," compiling a full manifest of materials to manufacture an end product.

- Manufacturing Decision Support and Supply Chain Vulnerability Tools: Incorporate data from past CEMAC analyses to show current and future product demand, manufacturing capacity, and trade flows.

CEMAC is seeking partners and sponsors to help us expand this analysis. Please contact us if you are interested in this project.